Understanding Aluminum Busbars: Essential Components in Automotive Electrical Systems

Release time:

2025-08-18

Aluminum busbars are integral components in the automotive electronics and electrical systems, often utilized within wiring harnesses for efficient power distribution

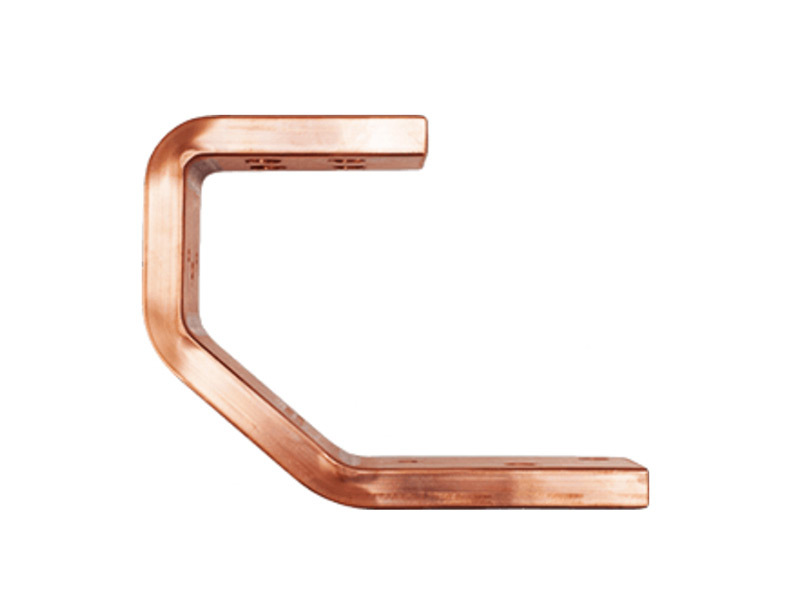

Aluminum busbars are integral components in the automotive electronics and electrical systems, often utilized within wiring harnesses for efficient power distribution. These conductive bars, typically made from aluminum due to its favorable electrical properties, play a crucial role in managing electrical currents within vehicles. Understanding the functionality and advantages of aluminum busbars can provide valuable insights for professionals in the automotive industry.

One of the primary advantages of aluminum busbars is their lightweight nature compared to copper alternatives. This characteristic is particularly beneficial in the automotive sector, where reducing vehicle weight can enhance fuel efficiency and overall performance. In addition to being lightweight, aluminum also exhibits excellent conductivity, making it a viable option for effective power transmission without significant energy losses.

Aluminum busbars are engineered to handle high currents, which is essential for modern vehicles that incorporate a multitude of electronic components. With the increasing complexity of automotive electrical systems, such as advanced driver-assistance systems (ADAS) and infotainment units, the demand for reliable power distribution solutions is more critical than ever. Properly designed aluminum busbars ensure that these systems receive the necessary power while minimizing the risk of overheating and electrical failures.

In addition to their performance benefits, aluminum busbars are also more resistant to corrosion compared to other metals. This characteristic is crucial in automotive applications, as vehicles are often exposed to harsh environmental conditions, including moisture and road salt. The corrosion resistance of aluminum helps maintain the integrity and longevity of the busbars, contributing to the overall durability of the electrical system.

When implementing aluminum busbars in automotive wiring harnesses, it is essential to consider factors such as cross-sectional area, busbar configuration, and thermal management. The cross-sectional area of the busbar should be sufficiently sized to handle the expected current load without overheating. Moreover, the layout of busbars within the harness should promote efficient airflow to dissipate heat, preventing potential thermal issues.

In conclusion, aluminum busbars are a vital component in the automotive electrical landscape, offering numerous benefits such as lightweight construction, excellent conductivity, and corrosion resistance. As the automotive industry continues to evolve with advancing technologies, the role of aluminum busbars will only become more pronounced. Understanding their applications and best practices for integration can significantly enhance the efficiency and reliability of automotive electrical systems, ensuring they meet the demands of modern vehicles.

Recommend

Language

Language